Choosing the right elevator for your project is about balancing daily usage needs with long-term cost savings. Machine Room Elevators are the top choice for large buildings and towers that require high capacity and heavy-duty performance. This system is specifically designed to handle continuous work pressure efficiently, making it the most reliable solution compared to other systems.

In terms of costs, this type is a smart investment because it saves you significantly on future operating and service expenses. While it requires a dedicated room for the motors, its simple mechanical design and the wide availability of spare parts make it the most cost-effective option for long-term maintenance. Additionally, having a separate room allows technicians to access and fix faults quickly, ensuring your elevator stays running smoothly without annoying interruptions.

What are Machine Room Elevators?

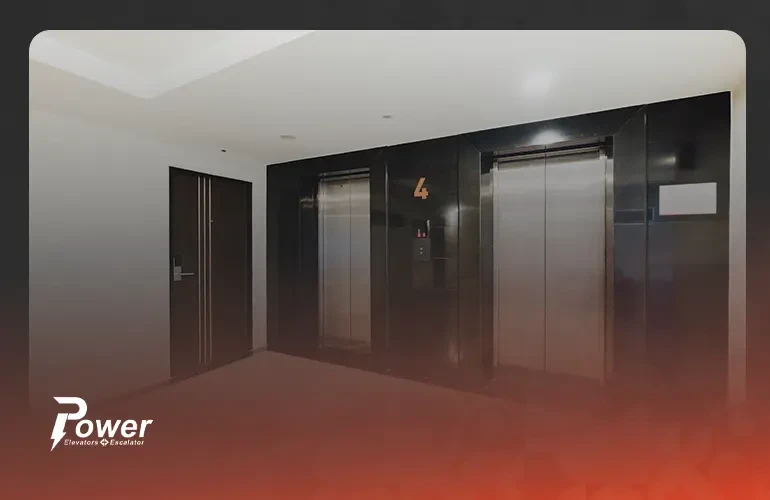

Machine Room elevators are the traditional and proven solution for large buildings and vital facilities. Simply put, they rely on a dedicated machine room located above the elevator shaft, which serves as a complete "Control Center." This system is built to work under high pressure without breakdowns, as the room protects sensitive equipment from dust, heat, and weather conditions. Machine Room Elevators house the core components:

-

Traction Unit (Motor): The powerful heart responsible for moving the elevator car smoothly and precisely.

-

Smart Control Panel: The "brain" that manages movement, organizes stops, and ensures the highest levels of safety.

-

Gear System: The mechanical system that balances and adjusts the elevator's speed according to the building's height.

-

Electrical Equipment: Including transformers and circuit breakers that ensure a stable power supply and protect the system.

It is a practical, long-lasting system that operates with total safety and smoothness, no matter how many floors or how busy the daily traffic is. Contact Power Elevator experts now for technical consultation and the best specifications for your project.

Features of Machine Room Elevators

At Power Elevator, we design our Machine Room systems to give you strong performance that lasts for years. Key benefits include:

-

Extreme Durability: Because the components are robust and housed in their own space, these elevators last for decades and easily handle the nonstop traffic of towers and malls.

-

Fast and Easy Maintenance: The separate room allows engineers to work comfortably and access any part quickly, ensuring the elevator is never out of service for long.

-

High Capacity and Speed: If your project requires heavy lifting or high speeds, this is your first choice. The design ensures total stability and balance regardless of the load.

-

Maximum Safety and Control: All machinery is in a locked room, preventing any unauthorized access. In emergencies, technicians can control the elevator manually with ease and safety.

-

Cost-Effective: Despite modern tech trends, this type remains the most economical long-term choice. Spare parts are affordable and widely available, and future upgrades are simple and low-cost.

Why Choose Power Elevator?

At Power Elevator, we believe trust is built on experience and maintained through commitment. Here is why we are the first choice for major institutions and developers:

-

40+ Years of Global & Local Experience: With over 25 years in the Egyptian market, we understand every technical detail and solve problems before they even happen.

-

Global Footprint: Operating in over 38 countries, we apply the latest international technologies in the elevator and escalator industry.

-

A Reputation You Can Trust: We are a certified partner for many government entities and major real estate developers in Egypt, with a strong partnership with "Capri."

-

Fully Licensed: Our company is officially registered with the Egyptian Federation for Construction & Building Contractors.

-

Expert Engineering Team: Our pros don't just install elevators; they develop complete systems like smart garages and conveyor belts tailored to your building's design.

-

Safety & Constant Support: We follow the highest global safety standards and serve over 100 clients who rely on us for regular maintenance and technical support.

Ready to start your project with a partner you can trust? Contact Power Elevator experts now to ask about our Machine Room Elevators. Let us help you choose the best technical solution for your building with the highest quality and the best price.